When you are working in connectivity special applications, our partner L-COM has one of the biggest catalogs, particularly for outdoor applications and harsh environments where a bigger flexibility is needed in the cables or high resistance in the connectors and cables.

There are different solutions when the temperatures are extreme or humidity conditions are special, also when we work in industrial harsh environments where EMI or RFI emissions are strong or if we work with corrosive materials.

What can we do when we need a communications network in environment with vibrations and shocks? Normal cables and connectors will not stand this situations and communications will be affected.

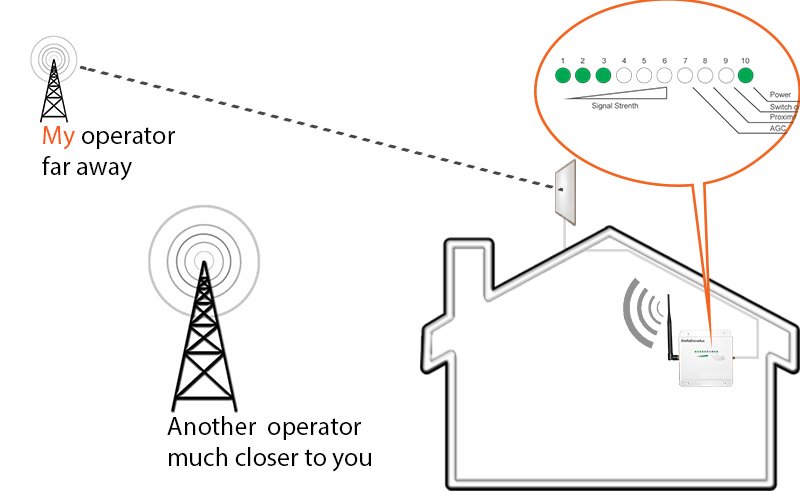

Outdoor Installations.

There is no need to go to a particular extreme environment to need minimal waterproof protection and an extended range of temperature for our equipment to work correctly. A digital signage panel installed outdoors already needs Ethernet and HDMI cables and connectors to be protected against water and high/low temperatures. UV proof cables and waterproof connectors will solve the problem and give a longer usable life to our installation. Different levels of protection are available IP67, IP68, IP69.

Vehicles and industrial applications

There are many mobility installations, like trains, metros, ferries or industrial equipment, where continuous vibration can bring many problems to communications installations. Specific connectivity solutions with connectors design to resists pulling and vibration are key. Using specific connectivity material can save money in maintenance operations and system failures.

High Mobility

In factory robots or machines that require to move thousands of times per minute and at the same time to be connected to the network. High flex cabling (both power and data) is proven to resist millions of bending.

Low Smoke Zero Halogen requirements

There are sometimes that due to legislation requirements, connectivity elements must be certified with low smoke emission or not to have halogen. You can find these elements looking for the references LSZH (Low Smoke Zero Halogen)

In any case if you have a special connectivity requirement, you can contact us for advice.